Our Line et Equinox electric violins have been available for almost one year now. We would like to show our production process for these instruments. That’s why we edited one video using production and playing sessions images.

The production of these electric violins is not as quick as the 1mn30 of this video. Each production step is described below.

Wood selection and preparation

Before anything happens, the wood is chosen carefully, then cut to specific dimensions.

The Equinox body is composed of one single piece of wood : ash.

The Line is a mix of two kinds of wood: beech and sipo. They are organized in parallel lines then assembled and glued together in order to get this particular aspect called ‘rayé-centré’ (stripe-centered).

Shape cutting with CNC

The first cutting of the shape is done with a CNC machine tools (Computer Numerical Control).

This step involves a pre-cutting of the complex electric violin shape.

Surfaces Finish

Pre-cuttings cannot be perfect and finished. Human intervention is necessary to finish each electric violin. A sanding of the full body is done to make it soft to the touch. Surfaces in contact with the strings and the musician’s body are sanded with precision to offer optimal playing comfort.

Wood post-treatments

Many post-treatments are applied in order to insure a perfect wood stability and to protect bodies from external harm.

The making of additional parts

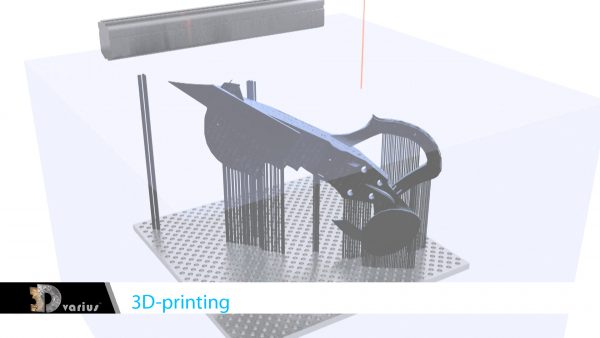

These additional parts are made in 3D-printing resin, wood and aluminum.

In 3D-printing resin, we create violin heads, the Equinox left-hand support or the half soundboard. We use stereolithography; we also print the 3Dvarius with this 3D-printing technology.

In wood, we make few parts like the Line left-hand or shoulder rest supports.

In aluminum, we make the tubes used to fix the wood body to its shoulder rest support. Aluminum is also used for all audio connections. We adapt them in function of our needs.

Then, all these parts are sanded, post-treated and varnished manually.

Pickup making

The pickup is THE key element for any electric violin. Without it, your electric violin would not be able to produce any sound. It picks up strings vibrations and turns them into an electrical signal which is, in turn, amplified.

Line violins are equipped by an S pickup, while the Equinox violins use an X pickup. Their production process is different and so is their sound. The X pickup is referred to as powerful, clear, precise, reactive, etc. ; and the S pickup as dark, warm, wide, etc.

Final assembly

We insert and prepare all parts on the electric violin (head, tuning pegs, jack output, bridge, etc.) Then the structure of the violin is subjected to actual string pressure for the first time.

Finally, each electric violin is controlled and tested with the help of different devices.

All steps are entirely done in France to create « Made in France 🇫🇷 » electric violins!

Special thanks to the CRITT Bois Occitanie and the PFT Bois Occitanie, and most particularly Guillaume and Aurélien.

Images: 3Dvarius and Unsplash – Simon Stankowski